LASER CUT

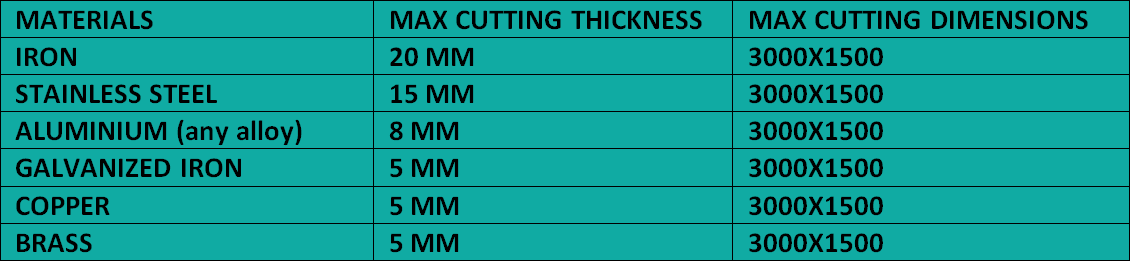

We have two PRIMA INDUSTRIE 4000 Watt LASER plants with a cutting capacity of up to 20 mm on iron and 15 mm on stainless steel. The maximum cutting size is 3000 × 1500. The systems are both equipped with automatic loading / unloading systems and sheet storage from 15 workstations that guarantee continuity of work even on unmanned shifts. The suction cup loading system avoids dents and scratches on the plates. We are able to make cuts without iron by providing the piece already ready for painting / galvanizing. The total opening of two sides of the working area and the cantilevered arm make the system very flexible and allow a quick change of machining for any cutting urgencies.

The computerized system for managing orders and work processes allows us to respond quickly to customer needs regarding delivery times, status of orders in progress and estimates.

We can make cuts on square tubes up to a maximum height of 100 mm: slots, holes, shapes or customized lettering. Infinite cutting possibilities for special perforated plates with slots or square holes.

We can also cut special sheets such as sheets with protective pvc, nets, pre-painted aluminum, perforated sheets, striated or embossed sheets.

PROCESSING

In our workshop we do not limit ourselves to laser cutting, but we also perform other types of processing to meet the greater number of needs of our customers.

We can therefore offer different services by having various machines:

• LASER FIBRA 3000X1500, 4000WATT “PRIMA POWER”

• CO2 LASER 3000X1500, 4000WATT “PRIMA POWER”

• TRUMPF BENDER TruBend 5170

• AUTOMATIC PUNCHING MACHINE

• 3 GADE” CNC BENDERS

• “GADE” SHEARS L = 3000 50/10 OF CUTTING

• 3 PRESSES FOR MOLDING

• “BIANCO” AUTOMATIC CUTTING MACHINE

• 3 COLUMN POINTERS

• 2 “FRONIUS” ARCOPULSATE WELDING MACHINES

• ROBOTIZED WELDER

• AUTOMATIC THREADING MACHINE

• COLUMN DRILLER AUTOMATIC BAR MOVEMENT

• “RAINER” PUNCHING MACHINE

• CALENDER

We are equipped to produce customized tanks and small assemblies. We can perform laser cuts on square tubes for endless applications, we can perform threaded inserts and fastner up to M8.

The sheet bending department currently has 4 CNC bending presses with capacities up to 170 Tons and 3 meters in length. For bending we can offer laser control of the bend angle.

These characteristics provide for the possibility of performing particularly difficult bending operations, from small quantities up to a high volume of work to satisfy the customer’s requests in a very short time.

PRODUCTS

We are able to supply special finished painting or galvanizing.

Availability for sampling, medium and high production.

We always have stock thicknesses from 0,8 to 20 mm of iron, from 0,6 to 15 mm of stainless steel, from 1 to 3 mm of galvanized sheet, from 1 to 5 mm of aluminum. special sheets such as satin stainless steel, mirror stainless steel, 2B-F1 stainless steel, S355jr sheet with certificates.

Cutting of high thicknesses up to 20 mm for the iron while maintaining precision and accuracy in the cut.

Possibility to bend sheet metal with maximum precision up to 3m thanks to CNC bending machines.

MERCEOLOGICAL SECTORS

Our customers operate in various sectors: this diversification has allowed us to come into contact with different types of products, allowing us to perfect specific knowledge and experience.

We operate in the following sectors:

• Equipment and systems for agriculture.

• Plants for the ceramic industry.

• Equipment and plants for the food industry.

• Equipment and systems for the medical industry.

• Construction equipment and systems.

• Equipment and plants for renewable energy industry.

• Other sectors

We are at your disposal for your questions and to quickly process estimates for the requested processing. To request a quotation, write to us at

info@atm-transmissions.com